Platinized Titanium Anode Mesh Titanium Anodizing Kit

Basic Info

| Model NO. | Specific size needs to be customized |

| Weave Characteristic | Tensile |

| Surface Treatment | Anodic Oxidation |

| Stamping Expanded Metal Mesh Category | Small Steel Plate Mesh |

| Galvanized Surface Treatment | Provided on Demand |

| Hot-galvanize Technique | Provided on Demand |

| Specifications | Mesh |

| Weight | Miniature |

| Grade | Gr1 Ti |

| Ti Content (%) | 99.99% |

| Product Exprience | Nearly 30 Years |

| Size | Customization |

| Certification | ISO,SGS |

| Transport Package | Pallet, Wooden Box |

| Specification | Specific size needs to be customized |

| Trademark | Boni |

| Origin | China |

| Production Capacity | 5000000pieces/Year |

Product Description

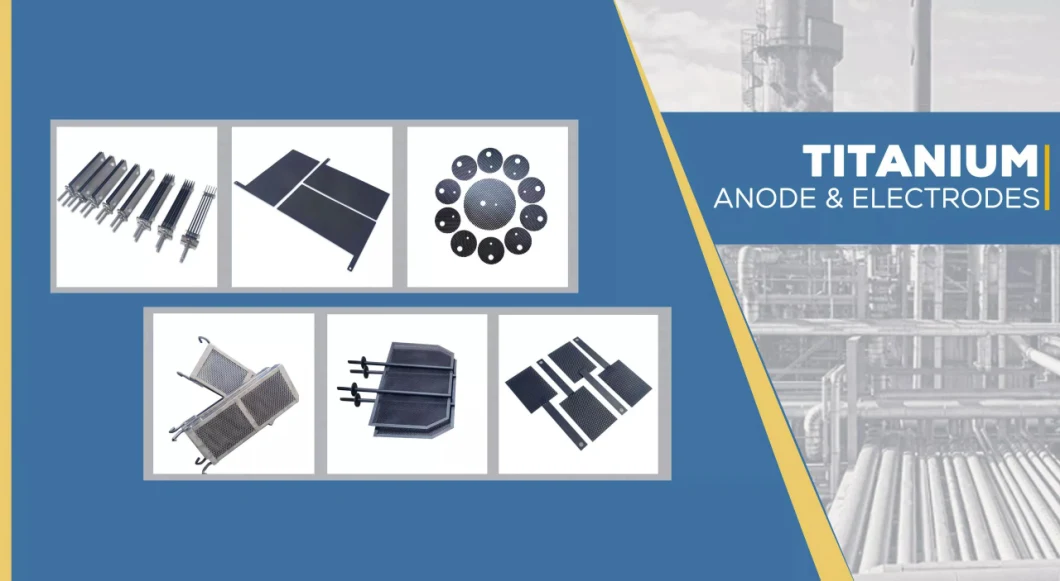

Boni Tech is a leading manufacturer of titanium electrodes in China, and its products are widely used in chemical, metallurgy, petroleum, textile and medicine, environmental protection, sports, marine and other fields. The main products are titanium-based ruthenium series, iridium series, platinum series and other titanium anodes. After more than ten years of development, the company has accumulated rich experience in titanium anode production and has the latest production technology.

Product Parameters

What is Titanium Anode?Titanium anode is called titanium-based metal oxide coated anodes (MMO). It is also called DSA anode, dimensionally stable anode

or dimensionally stable electrode (DSE). It uses titanium as the substrate (filament, rod, tube, plate, mesh) and coats the

surface of titanium substrate with precious metal coating to make it have good electrocatalytic activity, electrical conductivity

and oxidation resistance.

| ruthenium iridium coating mmo titanium anode | |

| Material | Gr1 titanium as substrate Coating: Mixed Ru-Ir oxide Mixed Ir-Ta oxide Mixed Ru-Ir-Sn oxide Mixed Ru-Ti oxide Platinum Lead oxide Pt-Ir oxide |

| Coating Thickness | MMO coating:8~12micron Platinum coating: 0.5-5micron |

| Parameter | 1. Current density≤2000A/M2 2. Temperature<60°C 3. PH 0.1~14 4. Max content of Fluoride ion is 200PPM |

| Dimension & Shape | 1. Plate/Tube/Rod/Mesh shape, different dimension is available 2. or according to client's drawing |

| Advantages | * The size of anode is stable and the distance between electrodes does not change during the electrolysis process, ensuring the electrolysis operation is carried out under stable tank voltage. * Working voltage low, so the power consumption is small, can save the power consumption, DC power consumption can be reduced by 10-20% * Titanium anode has a long working life could reach 5-7 years * It can overcome the dissolution problem of graphite anode and lead anode, avoiding the pollution of electrolyte and cathode products, thus greatly improving the purity of metal products * Increases current density and electrolysis efficiency * The oxides of the precious metals iridium and ruthenium are resistant to oxidation, so titanium electrodes are more resistant to corrosion * Titanium electrodes are lighter in weight and can reduce labor intensity compared to graphite and lead anodes * Lead anode deformation and short circuit problems can be avoided, thus improving efficiency. * Titanium anode's substrate shape and fabrication is easier and can be made with high precision Titanium anode's substrate can be used repeatedly without damage. |

| Applications | 1.Water ionizer or water electrolysis *Making alkaline and acidic water 2.Waste water treatment *Organic sewage treatment, *Chemical sewage treatment, *Pesticide sewage treatment, *Drinking water disinfection, *Bleaching & dyeing, *Swimming pool *Domestic sewage treatment, *Hospital sewage treatment, *Food industry disinfection etc. 3.Sodium Hypochlorite Generator & Chlorinator *Swimming pool water treatment *Water sterilization & water purification, *Anti-fouling,etc 4.Sea water electrolysis or Electrodialysis *Desalination, *Material recycling in the waste water, *Paper making, *Chemical, medical industry, *Light industry, *Metallurgy, *Making fresh water, etc. 5.Chlor-Alkali Industry 6.Electroplating *Electrolating Zn,Cr,Ni,Pd,Au.etc *Metal electroposition,such as Ag, Au, Rh, Pd,Cu, Zn, Ni,Cr… *Ag electrolysis *Electrolysis Copper Foil *Recover Hg 7.Battery Producing 8.Cathodic Protection |

| Packing | Carton or Plywood case |

| MOQ/Sample order | MOQ: Flexible /Sample Order: Acceptable |

Detailed Photos

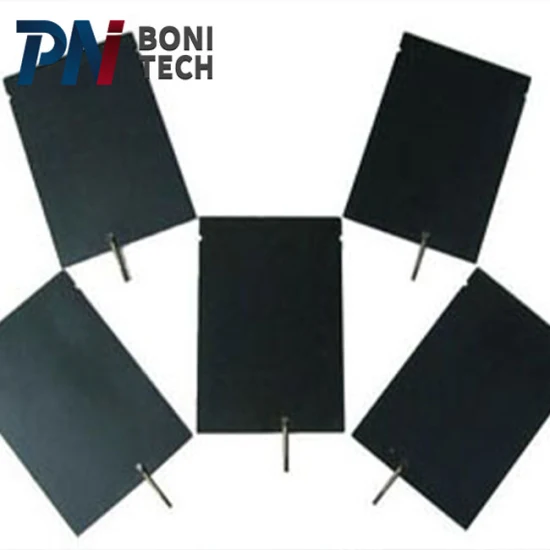

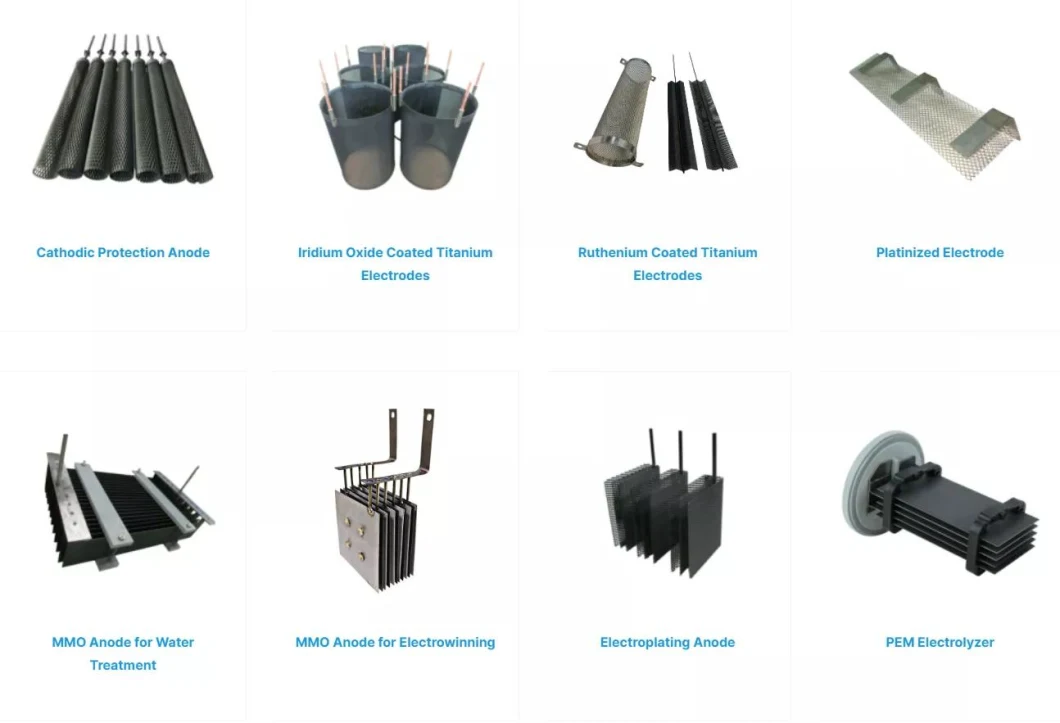

* Ruthenium-coated titanium electrode

This kind of electrode has low chlorine evolution overpotential and high oxygen evolution overpotential, mainly used in various chlorine evolution occasions, such as Chlor-alkali industry, cathodic protection, sodium hypochlorite production, sewage treatment, and so on. The coating includes an initial ruthenium-titanium coating (Ru-Ti), as well as one developed on this basis like Ru-Ir-Ti, Ru-Co-Ti, Ru-Co-Sn-Ti, Ru-Sn-Ti, Ru-Ti-Zr, Ru-Ti-La* Iridium coated titanium electrode

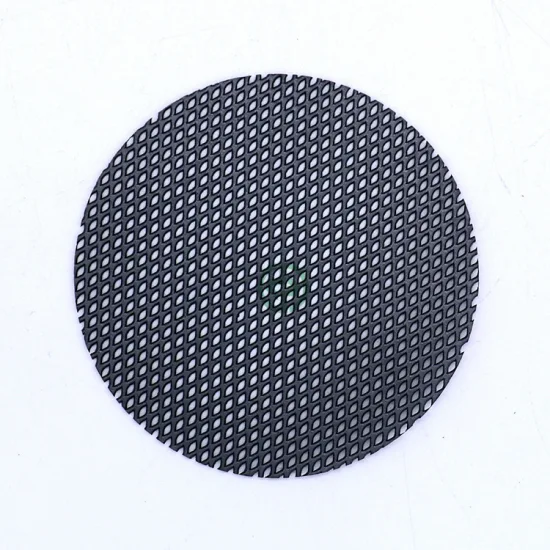

In the electrolytic process, such as electrolytic extraction of non-ferrous metals, electroplating industry, electrochemical reduction to make organic matter, etc., the design reaction of the anode is oxygen evolution reaction, and the electrolyte has a particularly strong oxidation, such as sulfuric acid, nitric acid, hydrogen peroxide and other environments. Therefore, it is hoped to develop a kind of anodic material with corrosion resistance and low oxygen evolution overpotential. Iridium coatingtitanium electrode is developed under this background. This kind of electrode coating includes Ir-Ta, Ir-Ta-Co, Ir-Ta-Sn coating. The ir-Ta coated titanium electrode is the most successful oxygen evolution electrode.*Platinum-plated anode

Titanium as substrate, the surface is plated with precious metal platinum, and the coating thickness is generally 1-5um. (Standard according to coating thickness)Platinum electrodes are suitable for small electrolysis applications in hydrogen evolution environments.The Shape

The geometry of the titanium anode is designed based on the principle that the substrate and the active coating can be firmly combined and easily molded to increase the surface area of the electrode.

The type of titanium used is pure titanium.

The substrate can be made to plate, tube, rod, mesh, and powder titanium Plate.

Manufacturing Technique

Company Profile

Packaging & Shipping

FAQ

1.

Q: Do you have XX model titanium anode?

A: Our titanium anode are all customized, so there are no models, according to your exact drawing, nearly any shape and size we could produce.

2.

Q: Can you produce the anode for our XX equipment/generator?

A: Yes, we can.But different clients have different equipment/generator, and need different anode size,so your anode drawing is required.

3.

Q: Which coating anode is suitable for me?

A: Your industry please. According to your application environment, we will give you professional advice.

4.

Q: How about the anode working current and voltage?

A: Titanium anode could be used for many industries, different industries have different suitable current and voltage take the following into consideration:

The suitable environment for our titanium anode:

Current density: bellow 2000A/M2

Temperature: 40-60ºC

There mustn't be any fluorine and cyanide ions in the electrolyte

5.

Q: How about the titanium anode lifetime?

A: The titanium anode lifetime for different industry aren't the same, half year to 50 years, according to your exact industry and environment, we will give you the guaranteed lifetime