Gr1 Ruthenium Iridium Coated Titanium Anode Plate for Electroplating

Overview GR1 Ruthenium Iridium Coated Titanium Anode Plate for Electroplating Our Advantages 1. Lower working voltage an

Basic Info

| Model NO. | ZR-005 |

| Coating Thickness | 0.5-5 Micron |

| Transport Package | Wooden Package, Carton Package |

| Specification | 54mm*74mm |

| Trademark | ZR |

| Origin | China |

| HS Code | 8108903210 |

| Production Capacity | 10000/Year |

Product Description

GR1 Ruthenium Iridium Coated Titanium Anode Plate for ElectroplatingOur Advantages1. Lower working voltage and small energy consumption

2. Titanium anodes have longer working life

3. Compared with soluble graphite anode and lead anode, titanium anodes are avoiding any pollution to electrolyte and products on cathode

4. Increasing current density is available, which can boost production efficiency

5. It can be worked in stronger corrosive medium or other special

| Base metal | Gr1/Gr2 |

| The coating of metal | RuO2+IrO2 |

| Current density range | <=10000mA/M² |

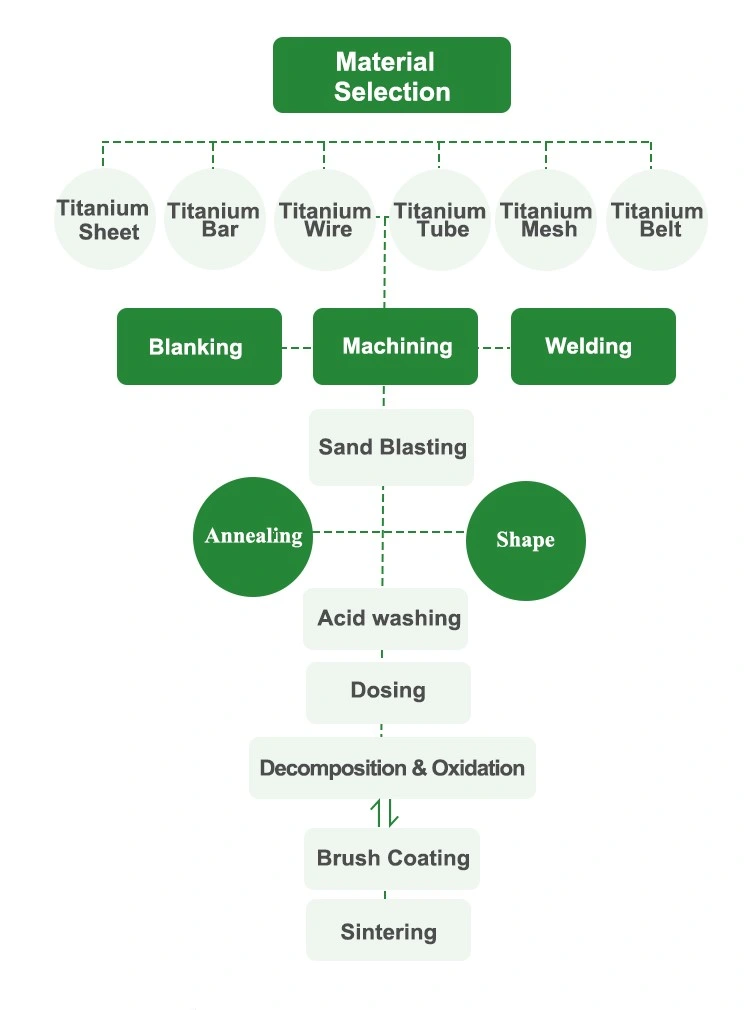

| Production process | Pickling, sintering, chain nano coating coverage |

| Precious metals content | 10g/M²-100g/M² |

| The electrode shape | Mesh, tubes, rods (custom) according to the requirement |

| Fluorine ion content | <50mg/L |

| The electrolyte PH value | 1-14 |

Certificates

FAQ

Send to us