Purity 93% Az91 Magnesium Sacrificial Anode and Cathodic Protection AISI

Basic Info

| Transport Package | Wooden Case |

| Specification | AZ31 |

| Trademark | SINOMAGNESIUM |

| Origin | Zhengzhou China |

| HS Code | 8104902090 |

| Production Capacity | 100, 000 Piece Per Month |

Product Description

Product Description

AZ91 Marine Magnesium-Based Alloy Sacrificial Anode For Cathodic Protection

Product Description

The use of magnesium sacrificial anodes for cathodic protection is an effective method to prevent metal corrosion. Magnesium alloy sacrificial anodes have the following characteristics: good corrosion resistance, no external DC power supply, automatic operation after installation, no maintenance, and less floor space , The project cost is low, and there is no interference with the external environment. Magnesium sacrificial anodes are widely used in petroleum pipelines, natural gas, gas pipelines and storage tanks; ports, ships, subsea pipelines, drilling platforms; airports, parking lots, bridges, power plants, municipal construction, water treatment plants, petrochemical plants, smelters , Corrosion protection of gas stations, water heaters, heat exchangers, evaporators, boilers and other equipment.

Cathodic protection is the most widely adopted electrochemical corrosion control technique and is accomplished by applying a direct cathodic protection current to a structure, effecting a change in potential from the natural corrosion potential (Ecorr) to a protective potential in the immunity region. Cathodic polarization of the structure controls the kinetics of the electrode processes occurring on the metal-electrolyte interface. The required cathodic current is supplied by means of an impressed current or attachment to a sacrificial anode. The metal structure in contact with an aqueous environment having a near neutral pH is thereby cathodically protected.- Commonly used in cathodic protection systems because Mg metal has a more negative potential than other galvanic materials. Our production plant uses high quality magnesium metal which exceeds normal standards used to manufacture anodes.- R, D and S Type anodes are available as stock items- Any item required that is not a stock item can be manufactured according to the customer specification. This would include Hull, Tank and Rectangular anodes.- All can be supplied in packaged forms.

Product Type: | Magnesium Anode |

Material: | Magnesium alloy AZ31B |

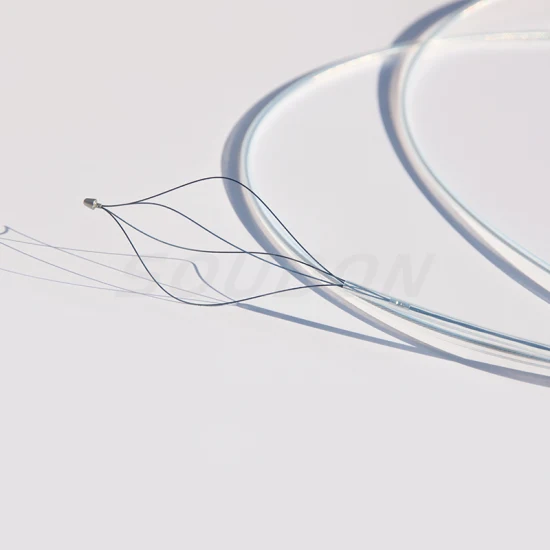

Differnet kinds: | Casting rod,Extruded rod,Rod with steel cap,Flexible anode rod |

Chemical composition: | Al:2.5-3.5%, Zn:0.6-1.4%,Mn:0.2-1.0%,Fe:0.005%max,, Cu:0.01%max,Ni:0.001%max,Si:0.1%max, Other:0.3%max,Mg:Balance |

Propertices: | Open-circuit voltage: 1.5-1.55V Close-circuit voltage:1.45-1.50V Actual capacitance: 1.105A.h/g Current efficiency:50%min |

Steel cap: | stainless steel,galvannized ,in black,coppper,etc. |

Application: | It mainly used in water heater,boiler,heat exchanger,water tank,etc. It can softing water,de-dirt residual,ensure water sanitation,water scale inhibition,protect inner tank,extend service life,etc. |

Feasures: | The extruded anode rod can be with or without steel core,can be with steel cap or only with screw;the size of cap/screw can be customilized by your specific requirements. Mainly different kinds of steel cap and screw available. |

Product Parameters

Type: AZ31B, ZK61M, AZ80A, AZ91D, M2M, ME20M, AZ40

Specification: Casting round bar billet(Φ3-160*3000)

Remarks: According to the requirements of sawing and heat treatmentUK Standard ZK60 WE43 Magnesium Metal Plate Small Modulus Of Elasticity

Magnesium Alloy Chemical composition:

According to the application requirements, produce high strength, heat resistant rare earth-Magnesium alloy extruded bars, tubes, wire rods, Welding wire and profiles set by national standard, ASTM, EN standard and autonomous development. The mechanical properties of the products are better than those set by various standards, and the products can be adjusted according to the concrete requirements of clients. The Magnesium products are used in different fields such as aerospace, rail transit, road traffic, pipeline transportation, textile machinery, 3C products, LED illumination etc.

High strength, heat resistant rare earth- magnesium alloy die castings set by national standard, ASTM, EN standard and autonomous development, such as steering wheel skeleton, the tank pan, power tools housing, electric wheel hub, 3C product shell and skeleton etc. The mechanical properties of the products are excellent and the microstructure of the products is homogeneous.

| Alloy Element | Type | Chemical Composition% | Other elements b | ||||||||||||

| Mg | Al | Zn | Mn | Ce | Zr | Si | Fe | Ca | Cu | Ni | Be | Sub-total | total | ||

| MgAlZn | AZ31B | Balance | 2.5-3.5 | 0.6-1.4 | 0.1-0.2 | --- | --- | ≤0.08 | ≤0.003 | ≤0.04 | ≤0.01 | ≤0.001 | --- | ≤0.05 | ≤0.30 |

| AZ40M | Balance | 3.0-4.0 | 0.2-0.8 | 0.15-0.5 | --- | --- | ≤0.10 | ≤0.05 | --- | ≤0.05 | ≤0.005 | ≤0.01 | ≤0.01 | ≤0.30 | |

| AZ80A | Balance | 7.8-9.2 | 0.2-0.8 | 0.12-0.5 | --- | --- | ≤0.10 | ≤0.005 | --- | ≤0.05 | ≤0.005 | --- | --- | ≤0.30 | |

| AZ91D | Balance | 8.5-9.5 | 0.45-0.9 | 0.17-0.4 | --- | --- | ≤0.08 | ≤0.004 | --- | ≤0.025 | ≤0.001 | 0.0005- | ≤0.01 | ≤0.30 | |

| 0.003 | |||||||||||||||

| MgMn | M2M | Balance | ≤0.20 | ≤0.30 | 1.3-2.5 | --- | --- | ≤0.10 | ≤0.05 | --- | ≤0.05 | ≤0.007 | ≤0.01 | ≤0.01 | ≤0.20 |

| MgZnZr | ZK61M | Balance | ≤0.05 | 5.0-6.0 | ≤0.10 | --- | 0.3-0.9 | ≤0.05 | ≤0.05 | --- | ≤0.05 | ≤0.005 | ≤0.01 | ≤0.01 | ≤0.30 |

| MgMnRe | ME20M | Balance | ≤0.20 | ≤0.30 | 1.32-2.2 | 0.15-0.35 | --- | ≤0.10 | ≤0.05 | --- | ≤0.05 | ≤0.007 | ≤0.01 | ≤0.01 | ≤0.30 |

Our Advantages

- Corrosion protection

- Protect water heater, water containers of steel structure

- Protect the gas pipeline in-home service polarization high resistance electrolytes (soil and water in the steel structure)

Aplication

1. TransportationSeat frame, armrest, small table panel, pedal, in-built profiles, driving frame, sleeper frame work, dashboard frame work etc.2. ElectronicsMagnesium alloys have excellent thin wall casting performance. They wall thickness of magnesium alloy die castings can reach 0.6-1.0mm, and the die castings can remain certain strength, stiffness and impact resistance. These performances are very consistent with development demand of lightweight, thin short and small for laptop. Mobile phone, digital camera, that makes the application of magnesium alloy grow sustainably.3. Aerospace industryEngine shell, parts. Skin and cabin, frame, holder, wingtip, aileron, fuel tank, gearbox, airscrew, seat, undercarriage, all kinds of shell, siding, clapboard etc.4. Military industryPanzer tank vehicle, torpedo, guided missile, aircraft / spacecraft, military electronic equipment, military statellite.5. Medical industryMedical device and implant material.

Detailed Photos

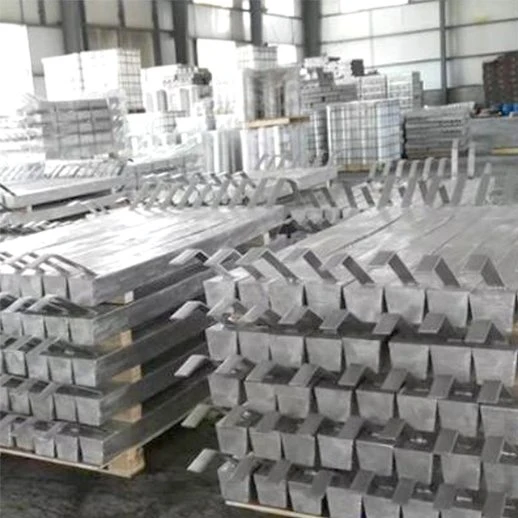

Workshop

Packaging & Shipping

FAQ

Q: Do you provide OEM/ODM service?

A: Yes, OEM/ODM is welcome, we have the professional R&D team.

They work for you all the time (design, tooling/mould, sample, mass production).

Q: How can I know your company further?

A: Please leave message in website with you email or phone number, the sales manager will send the catalogue to you by email or call you directly.

Also welcome to visit our company!

Q: How can I get the quotation, sample, mass production?

A: Please show us the sizes/drawing of the parts you need, our business director will show you detailed quotation with the lead time of sample and mass production.

Q: How do you control the quality?

A: The products are produced under ISO9001 & SGS certificate.

The documents of PPAPIII, FAI, inspection Report also will be sent to you for Checking if needed.

Company Profile

Sino Zheng Industrial Inc. is one of a leading & professional suppliers of forging magnesium wheel, magnesium welding wire, magnesium rod as well as magnesium alloy profiles in Zhengzhou China. Our company uses advanced production technology and automation equipment to ensure the high quality and high stability of magnesium alloys. Our magnesium alloy rods are refined by a special process, with small grains, uniform inside and outside, low impurity content, and no peeling; the company's die-casting production line uses these magnesium alloy rods as raw materials to produce magnesium alloy bicycle frames, rims, and magnesium alloys. High-quality products such as crossbow racks.

Our company has now developed a formula and process for producing high-quality magnesium alloys, which are inimitable. Magnesium alloy welding wire produced with this formula and process can realize compatible welding between different magnesium alloy materials, that is, different materials of magnesium alloy can be welded with one kind of welding wire, and have the advantages of small thermal effect zone, deep welding penetration, and no blistering. In particular, the 1.2mm magnesium alloy welding wire produced uses a one-time extrusion process to replace the original extrusion and then drawing process. Relying on the excellent technical team in the industry, the company continuously expands the application range of magnesium alloy materials through technological innovation, product innovation and process innovation, and contributes to the development of my country's magnesium alloy industry.

Our company is currently a professional manufacturer of magnesium alloy welding wire in China. The magnesium alloy welding wire produced by the company has specifications such as 1.2mm, 2.4mm, 3.2mm, etc., all of which are produced by one-time extrusion molding process with stable quality. With these magnesium alloy welding wires, different types of magnesium alloys can be welded together. The heat effect zone of the welded parts is small and the weld strength is higher than the non-welded zone. The bicycle frames welded with these magnesium alloy welding wires can achieve more than 150,000 vibration tests without cracks.

The application of magnesium alloy welding wire completely solves welding problem of magnesium alloys, can promote the wide application of magnesium alloys in military, aerospace, and civil applications, can increase the total application of magnesium alloys in the country, and maximize the high reserves of magnesium alloys in the country propelling the magnesium industry into a stage of rapid development will bring a material revolution to our country.